VOYGR Power Plants

The Future of Nuclear

VOYGR™ SMR plants are powered by our innovative NuScale Power Module™, the first and only small modular reactor (SMR) to receive design approval from the U.S. Nuclear Regulatory Commission (NRC). The NuScale Power Module design is based on proven pressurized water-cooled reactor technology, and was developed to supply energy for electrical generation, district heating, desalination, commercial-scale hydrogen production and other process heat applications.

VOYGR Plant Models

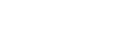

VOYGR-12

The VOYGR-12 SMR plant can generate 924 MWe on just 0.05 square miles, compared to 94 square miles for wind and 17 square miles for solar. This makes it an ideal option for generating carbon-free power in locations with space constraints, such as retired coal plant sites. The VOYGR-12's always-on capabilities also make it an attractive solution as an emergency power source. Following a catastrophic loss of infrastructure, a VOYGR-12 can power a mission critical facility micro-grid at 154 MWe for 12 years without new fuel.

Product Overview

| Generating Capacity | 924 MWe (77 MWe per module) |

|---|---|

| Capacity Factor | >95 percent |

| Module Dimensions | 76' x 15' cylindrical containment vessel with reactor and steam generator |

| Module Weight | ~700 tons in total are shipped from the factory in three segments via truck, rail, or barge |

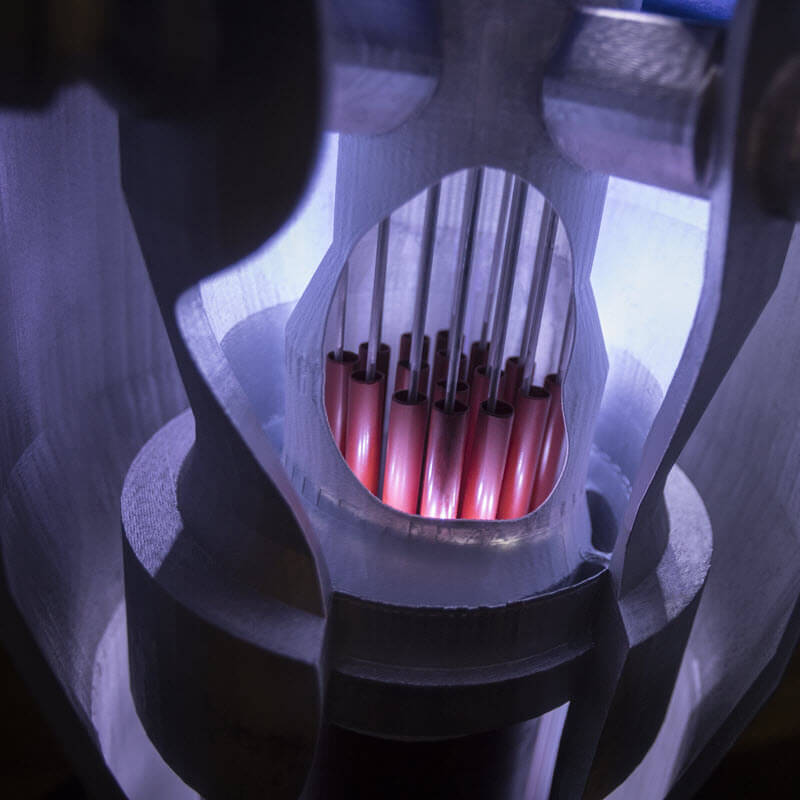

| Fuel | Standard LWR fuel in a 17 x 17 configuration, each assembly 2 meters (~ 6 ft.) in length |

| Refueling Cycle | Up to 21 months with fuel enriched at less than 5 percent |

VOYGR-6

A VOYGR-6 SMR plant is an affordable option for transitioning to carbon-free energy generation. When coupled to a 230,000 barrels per day refinery, a VOYGR-6 can eliminate approximately 40% of overall plant emissions (175 MT/hr reduction in CO2). Scale up to a 12-module plant as capacity needs increase.

Product Overview

| Generating Capacity | 462 MWe (77 MWe per module) |

|---|---|

| Capacity Factor | >95 percent |

| Module Dimensions | 76' x 15' cylindrical containment vessel with reactor and steam generator |

| Module Weight | ~700 tons in total are shipped from the factory in three segments via truck, rail, or barge |

| Fuel | Standard LWR fuel in a 17 x 17 configuration, each assembly 2 meters (~ 6 ft.) in length |

| Refueling Cycle | Up to 21 months with fuel enriched at less than 5 percent |

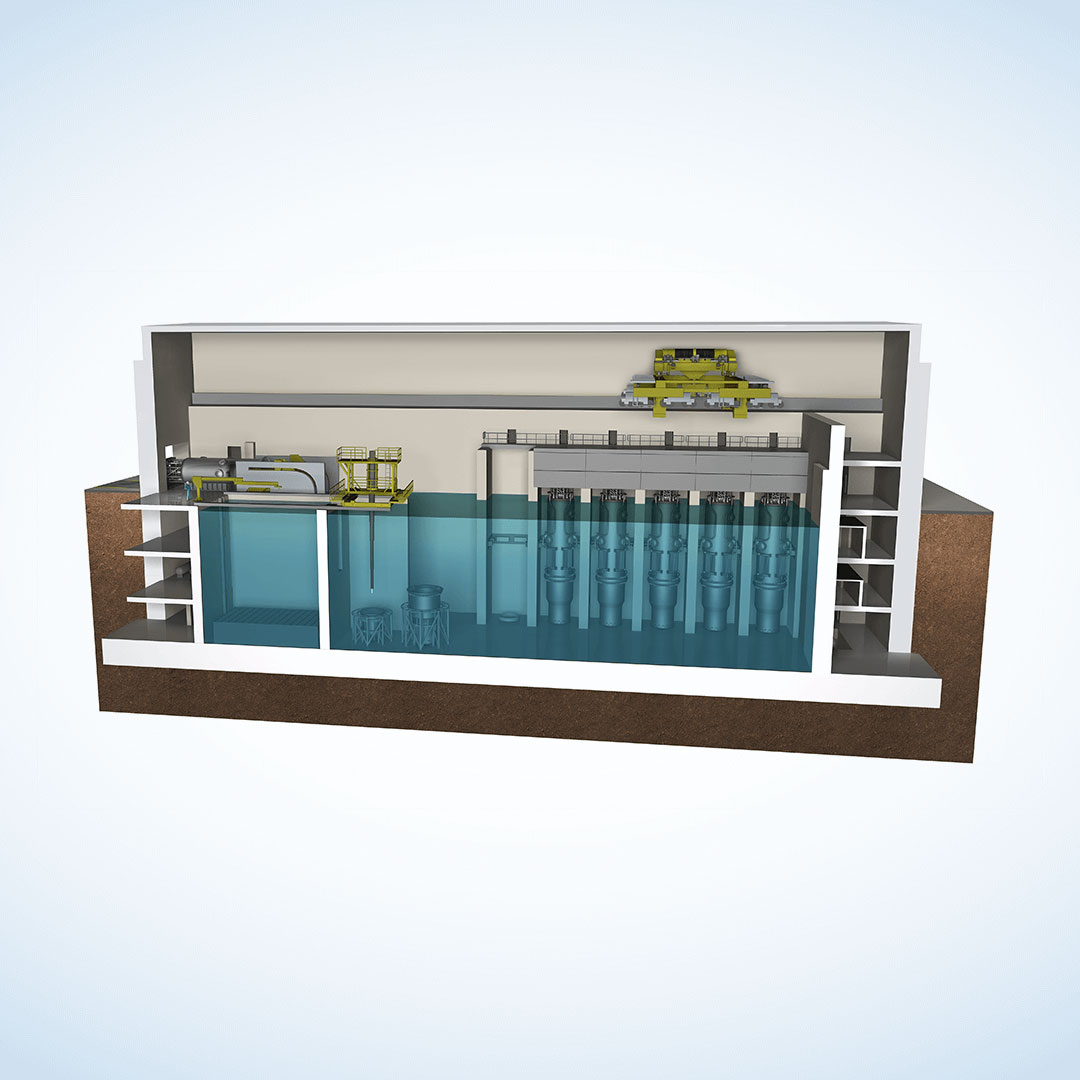

VOYGR-4

For lower generating capacity needs, the VOYGR-4 SMR plant is a small, but powerful solution. When coupled to a desalination plant, a VOYGR-4 can provide all of the water necessary for a city the size of Cape Town, South Africa (4.6 million people). Easily scale up to a 6- or 12-module plant as your capacity requirements increase.

Product Overview

| Generating Capacity | 308 MWe (77 MWe per module) |

|---|---|

| Capacity Factor | >95 percent |

| Module Dimensions | 76' x 15' cylindrical containment vessel with reactor and steam generator |

| Module Weight | ~700 tons in total are shipped from the factory in three segments via truck, rail, or barge |

| Fuel | Standard LWR fuel in a 17 x 17 configuration, each assembly 2 meters (~ 6 ft.) in length |

| Refueling Cycle | Up to 21 months with fuel enriched at less than 5 percent |

The VOYGR Advantage